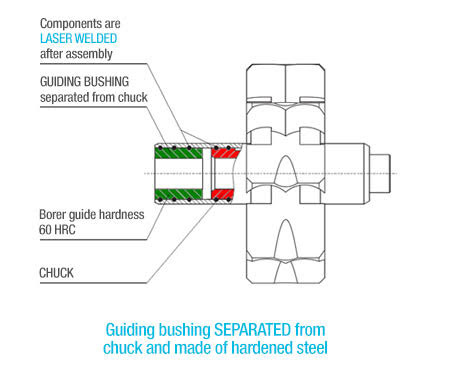

Are you troubled with imprecise work of your handpiece? Dou your customers complain about high vibrations of their handpieces or overall, they are not satisfied with the life time of rotors? The solution to these problems is a guiding bushing (a hole into which bur is inserted) non-resistance to wear. The guiding bushing must be made of carbide or hardened steel and it must be separated from chuck (see Fig. below).

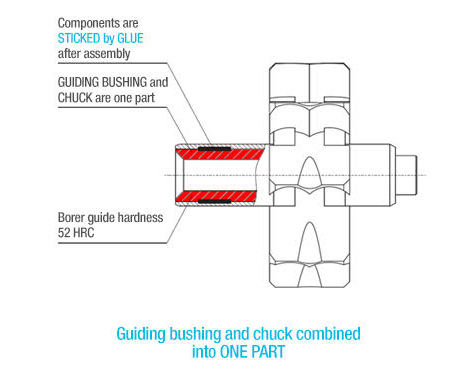

Many after-market producers of dental handpiece rotors combine the chuck and guiding bushing into one part because it simplifies the spindle design and thus saves costs. But this technique is not optimal for the wear resistance. Pressures that are put on the bur during operation can create wear in the guiding bushing, giving the bur more space to move radially. The greater is the radial play of a bur the less precise is the work with a handpiece. Increased radial play also shortens the bearing lifetime and consequently the lifetime of the whole rotor.